WORLDiscoveries is part of C4 along with the universities and some of the research institutions affiliated with the University of Waterloo, McMaster University, Wilfred Laurier University, the University of Windsor and the University of Guelph. The C4 objective is to coordinate, cooperate and collaborate to commercialize technologies.

Getting any business off the ground is daunting on the best of days. But for an innovative medical or scientific research initiative to take flight, it requires a great deal of financial support at the very least. WORLDiscoveries is focused on helping innovative start-ups secure early-stage finance to get closer to commercialization.

The Western Innovation Fund (WIF) was launched in 2004 and has awarded $2.1 million to researchers at The University of Western Ontario. “These awards leverage an additional $2.8 million in other grants and industry investment,” says Nadine Weedmark, Administration and Budget Manager at WORLDiscoveries. “There are three competitions per year, and applicants can request up to $50,000 per project.”

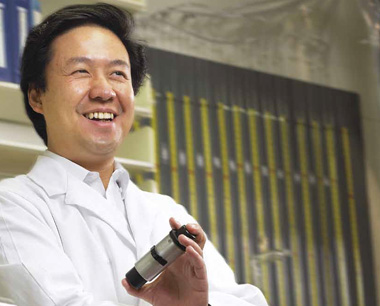

Proposals are evaluated by university and industry professionals with extensive commercialization experience. “This past year, WIF has assisted in getting two spin-off companies established – DQE Instruments and ENT SimTech,” says Weedmark. “And six licence agreements have been signed as a result of the technology moving forward from WIF funds.”

Another source of proof-of-principle funding is through the Ontario government’s program known as the C4 Consortium. WORLDiscoveries is part of C4 along with the universities and some of the research institutions affiliated with the University of Waterloo, McMaster University, Wilfred Laurier University, the University of Windsor and the University of Guelph.

The C4 objective is to coordinate, cooperate and collaborate to commercialize technologies. “At the most basic level C4 means we work well together and share best practices,” says Weedmark. “C4 gives us all more of a presence in Southwestern Ontario and clout in technology transfer. We become a team of 40 minds working together, instead of just 15 people.”

The C4 proof-of-principle fund was established in the fall of 2007, and Western researchers have won over $300,000 towards their commercialization projects to date. “Western is known for some specialties and the system recognizes that each institution has different strengths,” says Weedmark. “It is about the small wins that give us big traction.”

Read more